The stepwise approach:

Riantics now use Experior in all phases

The stepwise approach: Riantics now use Experior in all phases

Riantics have had great success in numerous applications of Experior, and a stepwise approach to implementing emulation has been instrumental in this. Their advice is to start out simple with the best business case and grow from there.

As one of the final stages before getting production up and running, the timing during commissioning is tight – whether you’re setting up new automation systems, equipment or code, or you’re reconfiguring existing systems.

They know this at the Danish system supplier Riantics. When they supply their Layer Picker solution for internal logistics to their customers, every second counts, and that is why they test the control software thoroughly beforehand.

“When we know that our code works correctly before going onsite, we can focus our work on the surroundings such as sensors, cables, motors, etc., and save time”, says Jan Kristiansen who is Head of Standardization & Software Development at Riantics.

Jan Kristiansen

In his department, they develop the PLC code for Riantics’ solutions, and in this process low level emulation in Experior is important. Emulation – or virtual commissioning – is offsite testing of control logic using a 3D model of the system connected to the control logic that will control the model as it would the real system. With the 3D model, you can perform numerous software tests, significantly reducing time spent on programming and onsite testing.

Experior cuts commissioning time and minimizes risk

In itself, low level emulation thus has many benefits for Riantics, but the company also test their high level controls with high level emulation is Experior. On a detailed emulation model of the entire installation in Experior, they perform early, comprehensive and cost-efficient tests of the Warehouse Control System (WCS) before the planned onsite commissioning.

“Previously, we had to find the errors in the controls by running live tests on the real system, when we were standing onsite, but now we go onsite with a WCS that we know will work. That’s the big difference,” Jan Kristensen says.

When Riantics emulate both their PLC code and WCS, the onsite integration will be easier, as all the code is introduced in a better-tested state than previously possible. This contributes to a better commissioning phase and start up.

“In our first project with virtual testing, we saved 30-40 percent of the commissioning time on the conveyor system – simply because the code was pretested in Experior,” Jan Kristensen says.

He also mentions that the use of emulation in Experior reduces the customers’ risks:

“When the customers start using the new systems, it will take less time to get working correctly and there will be less mistakes,” he says.

But it is not only in the development and commissioning phases, where Riantics benefit from using Experior. When selling new solutions to customers, Riantics use simulations in Experior as a tool to prove the solution.

“By simulating the flow of the system in Experior, we can make sure that we can deliver the capacities that we sell our system on,” Jan Kristiansen says about the simulations that among other things will demonstrate bottlenecks, accumulation needs and the required staffing of the solution.

Stepwise approach to the implementation of emulation

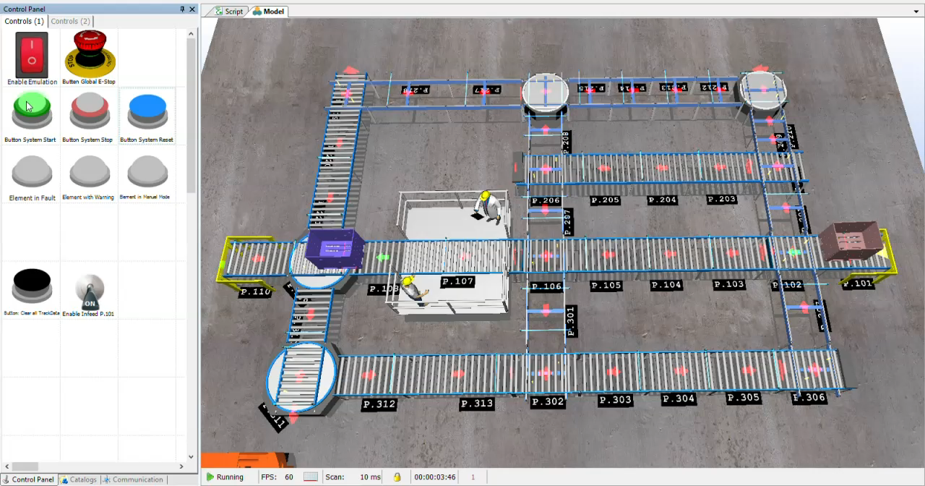

A Layer Picker system in Experior

A major key to Riantics’ success in integrating the use of Experior in their work processes is a stepwise approach. For several years, Riantics has integrated Experior to more and more phases of their work, and the low level emulation being done in Jan Kristensen’s department was one of the latest phases, where Experior was introduced.

“We started out low-tech with a simple 3D model of a conveyor system built in Experior using existing Experior components that we knew worked. Then we could focus on the essential part – testing our own PLC code,” says Jan Kristensen.

They used this setup to develop and test a new PLC code in Experior, and they were able to successfully integrate the code in a real system in record time, because it was fully tested in the virtual world.

“The case is the same, when we go onsite with a customer. We know that the code works, and that is the major difference, when using emulation in Experior,” Jan Kristensen says.

Low level emulation model in Experior used to test the new PLC code

These early successes have paved the way for Jan Kristensen’s department begin to extend the emulation approach to also cover rail systems, cranes and gantry systems. Based on these experiences, he has an advice for other companies who want to start using emulation:

“Start small and grow big. That is the most important point to be made, when talking about implementing emulation. It might be tempting to start emulating your biggest and most complex product first, but that is most likely not the best business case for early successes,” Jan Kristensen says.