What is virtual commissioning?

How to improve control software quality and reduce both time and costs with virtual commissioning

Virtual commissioning with Experior will help you achieve a higher quality automation solution, while saving you time and money.

The challenges in the manufacturing and logistics industries are mounting. To keep up with the unprecedented pressure of competition, many companies introduce ever more sophisticated automation systems.

But it is a complicated task to get automation systems to work fluently, and that is why virtual commissioning is becoming a business imperative.

What is virtual commissioning?

To coordinate an automation system, you need sophisticated control software, and the integration testing of these controls prior to start-up of the system is now a critical phase.

Unfortunately, nearly than two thirds of the commissioning time is spent testing and fixing errors in the control software, when the hardware has already been assembled on-site*.

Such tests are expensive, time consuming and may cause hardware damage.

Here is where virtual commissioning comes in to the picture.

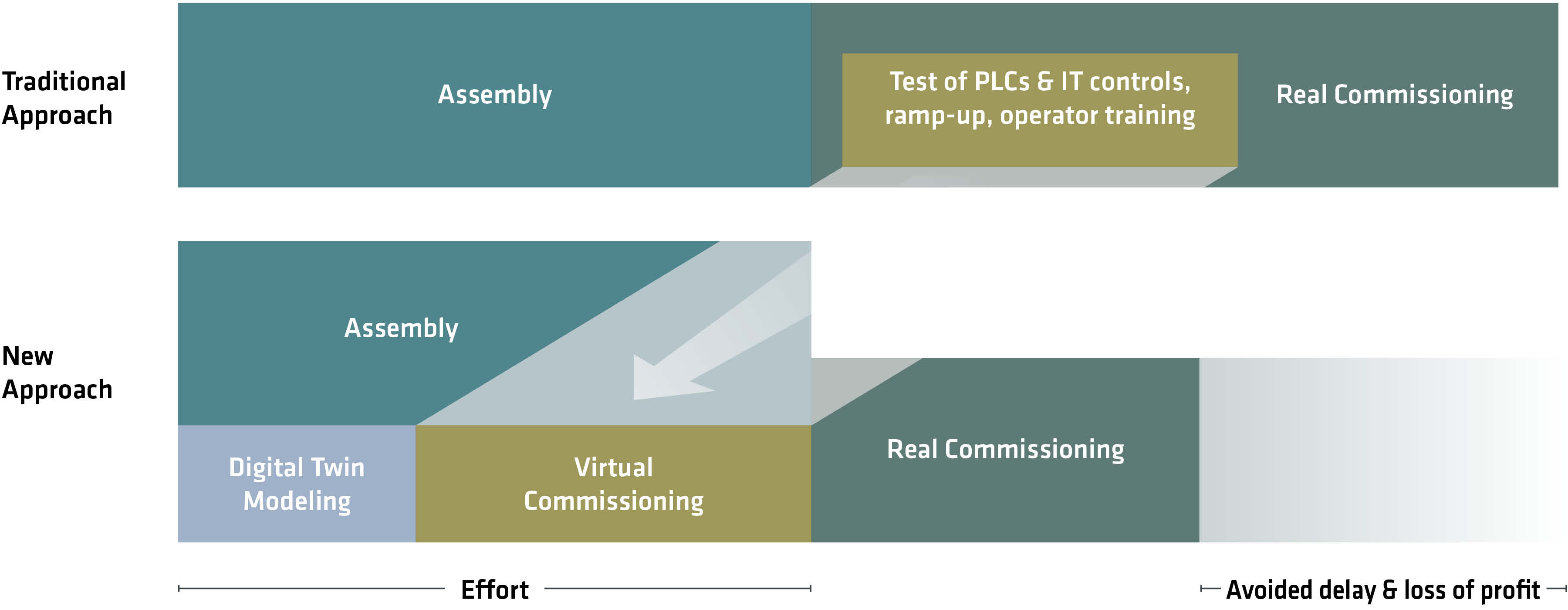

With a software platform for Digital Twin modeling and virtual commissioning – like Xcelgo’s Experior – you can test, debug and validate the software in front of your computer – before you connect it to the real system.

Research shows that virtual commissioning can improve the control software quality in terms of fulfilled requirements by more than 100% and reduce the commissioning time by 75%*.

Contact us here to learn how YOUR business can reap the benefits of virtual commissioning.

Benefits of virtual commissioning

With virtual commissioning you will:

- Reduce on-site testing

- Reduce project lead time

- Reduce project cost

- Improve software quality

- Improve productivity

- Improve working conditions

Virtual commissioning can be understood in a much broader sense than the name suggests. A well-integrated virtual commissioning model has potential applications in many other phases of the automation system lifecycle, such as operator training, improved after-sales and ongoing optimization, sales and marketing, and as a collaboration platform. See all the applications here.

*Reinhart, G. & Wünsch, G. (2007). Economic application of virtual commissioning to mechatronic. Production Engineering – Research and Development, 1(4), 371–379.